- COMPANY OVERVIEW

- About Us

- Management Team

- Contact Us

- Vision

- Our Values & Our Purpose

- We Offer

- Our Clients

- Ongoing Project

- Ongoing Project Catering

- We Serve

- Our STRATEGY

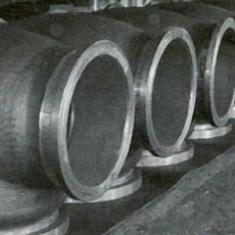

ISF carries a full range of carbon and alloy pipe, both for structural and process applications, in a variety of material offerings, as well as all complementary pipe components, fittings and flanges.

Welded (SAW, ERW/HFI) and seamless tubular and hollow sections suitable for conductor pipe, riser pipe, tendon pipe, jacket members and other structural onshore and offshore applications

High-density polyethylene pipe is a cost effective solution for a broad range of piping requirements in oilfield and gas gathering, gas distribution and industrial and mining applications. HDPE's corrosion, abrasion and chemical resistant properties make it suitable for a variety of abrasive slurries, chemicals, compressed gases and fuels. Joined by heat fusion, this pipe is a leak free with excellent flow characteristics. Lightweight and flexible, it also is easy to transport, handle and install, which means cost savings.